What We do

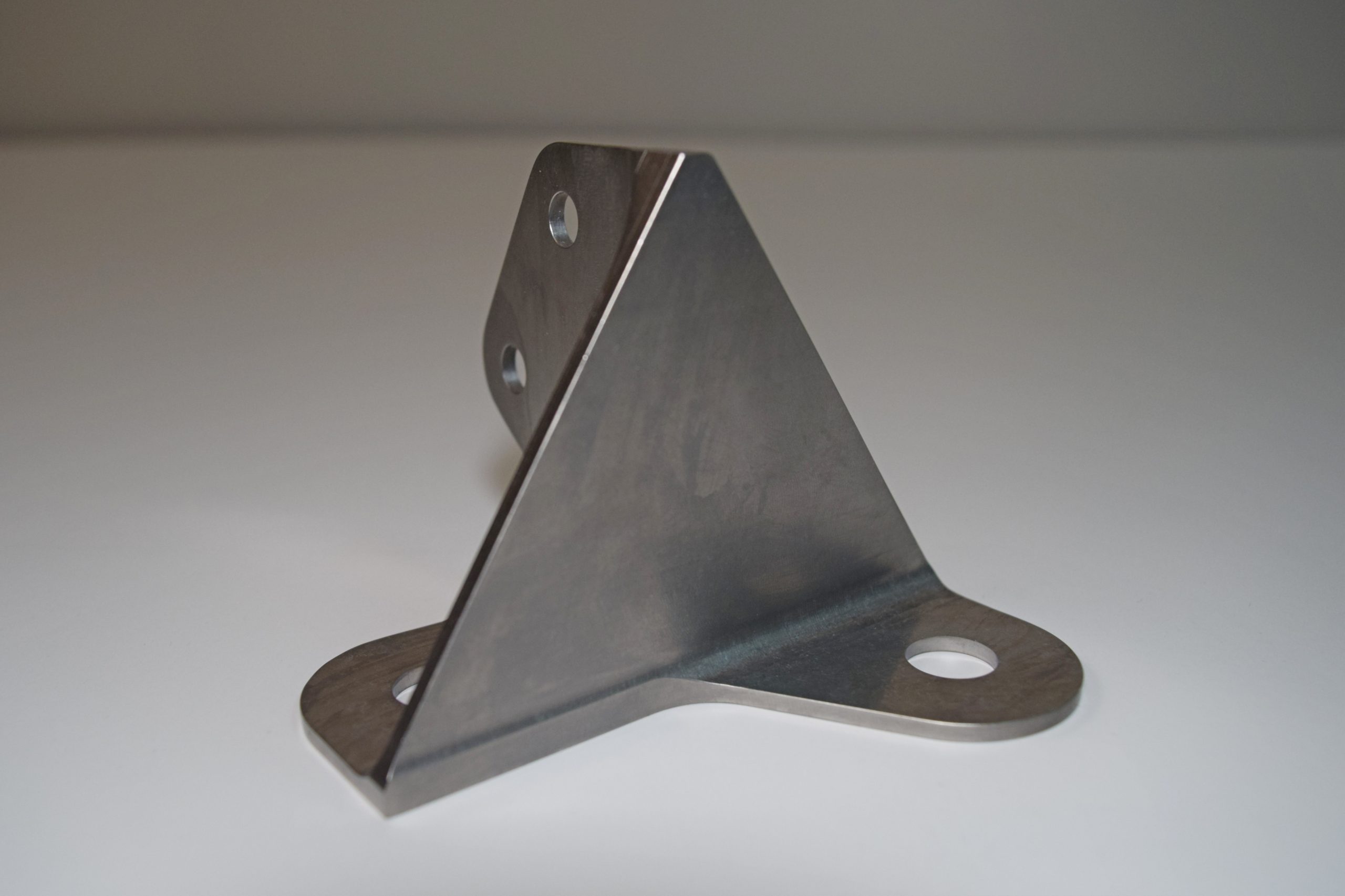

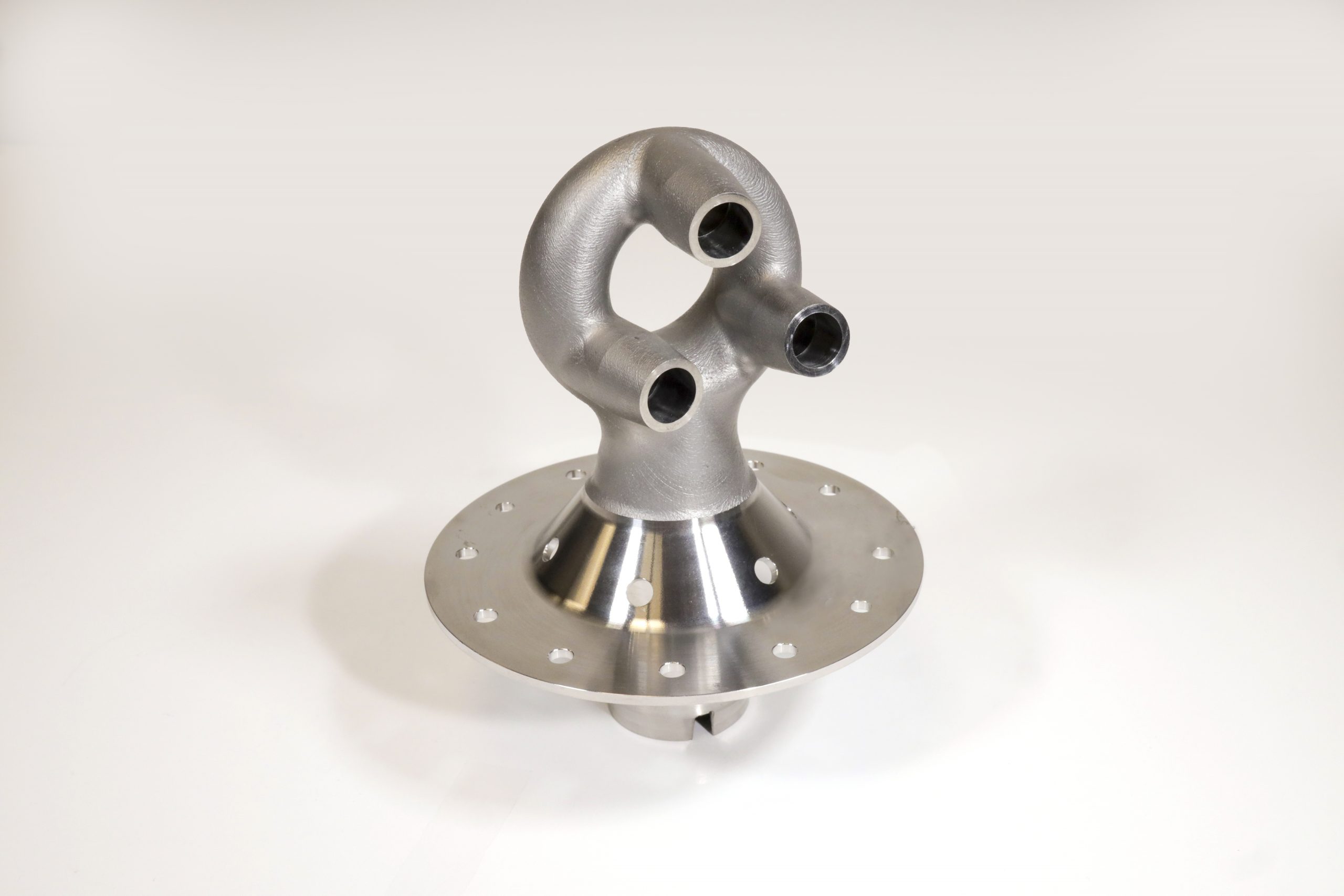

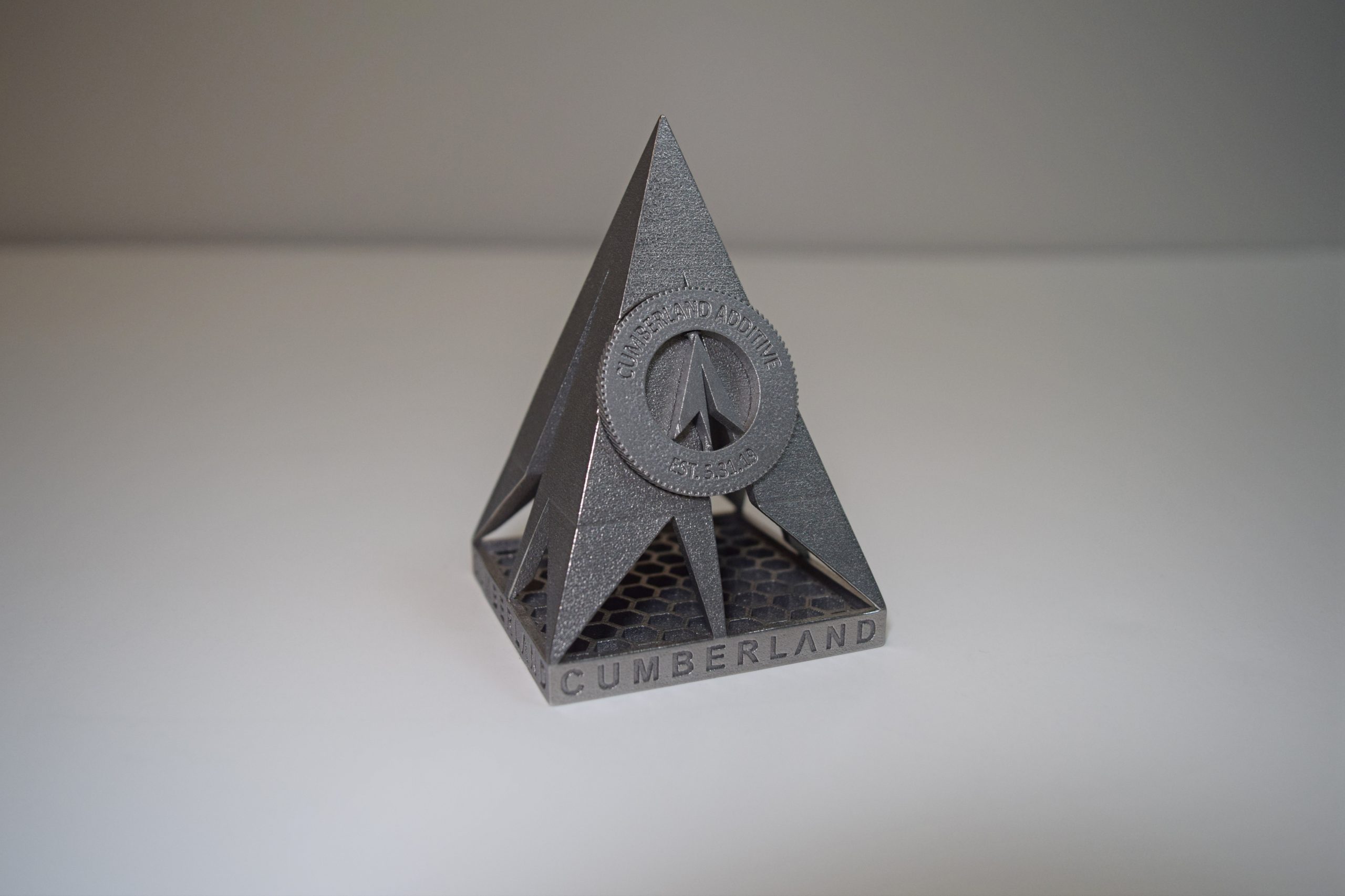

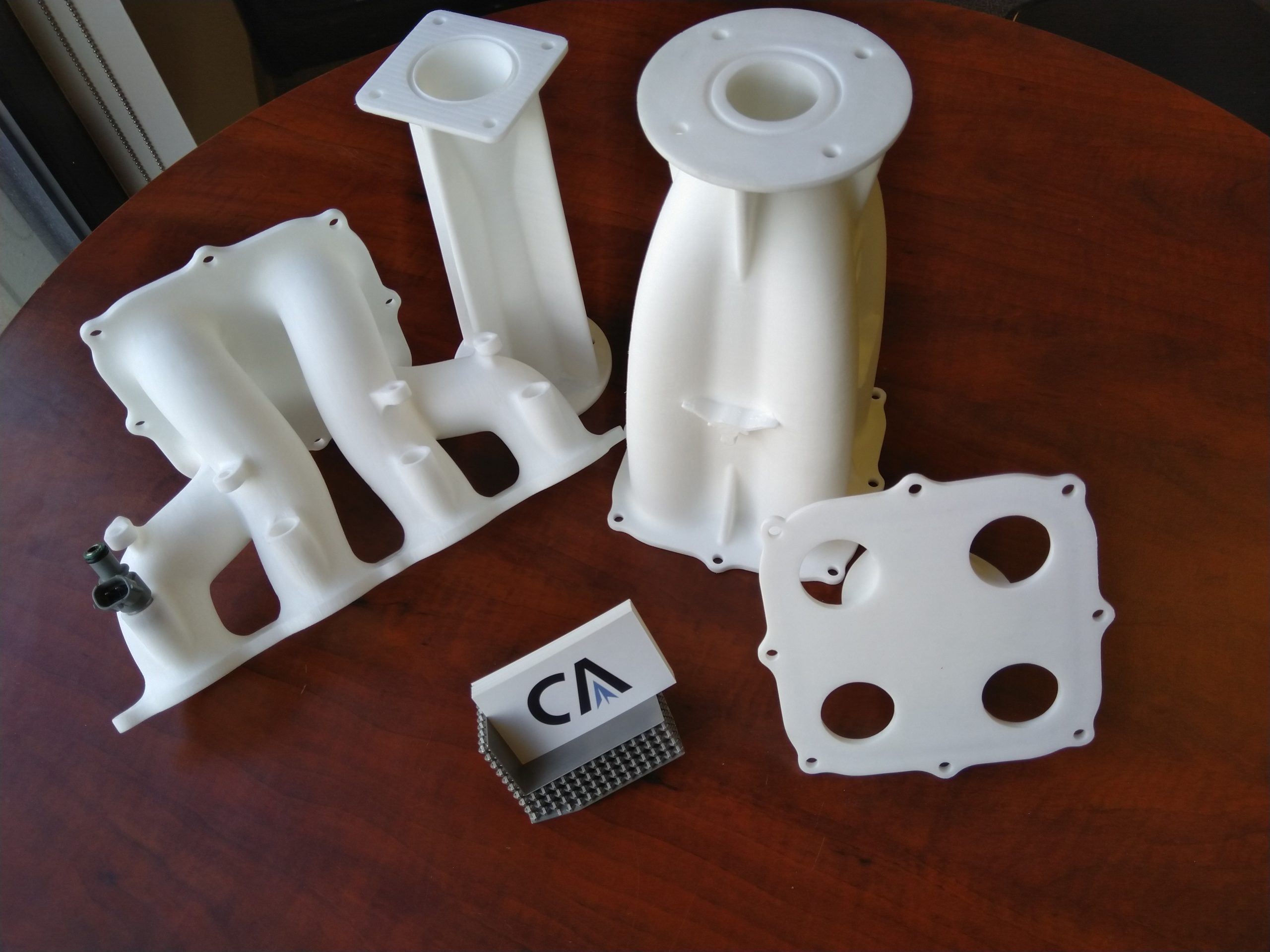

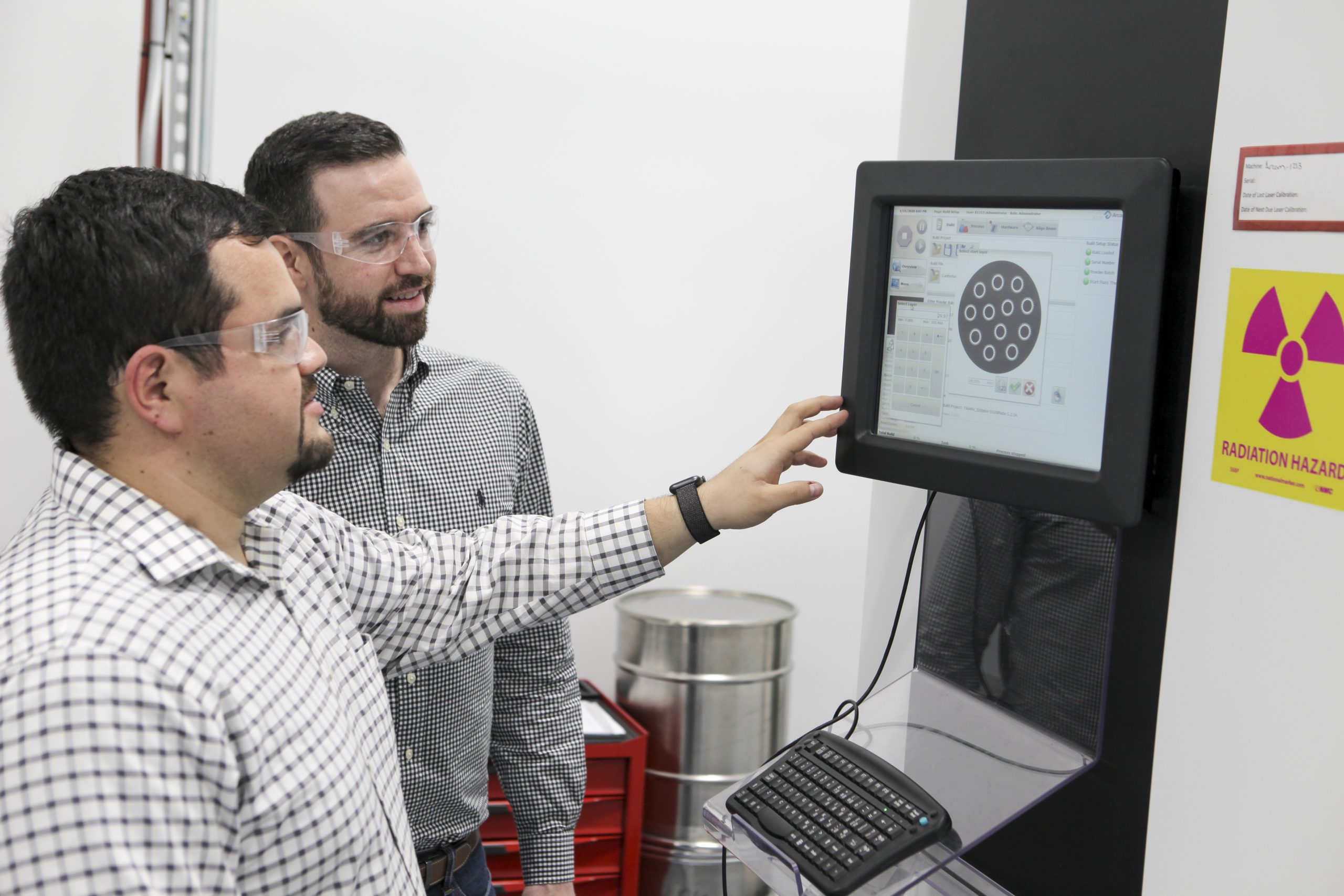

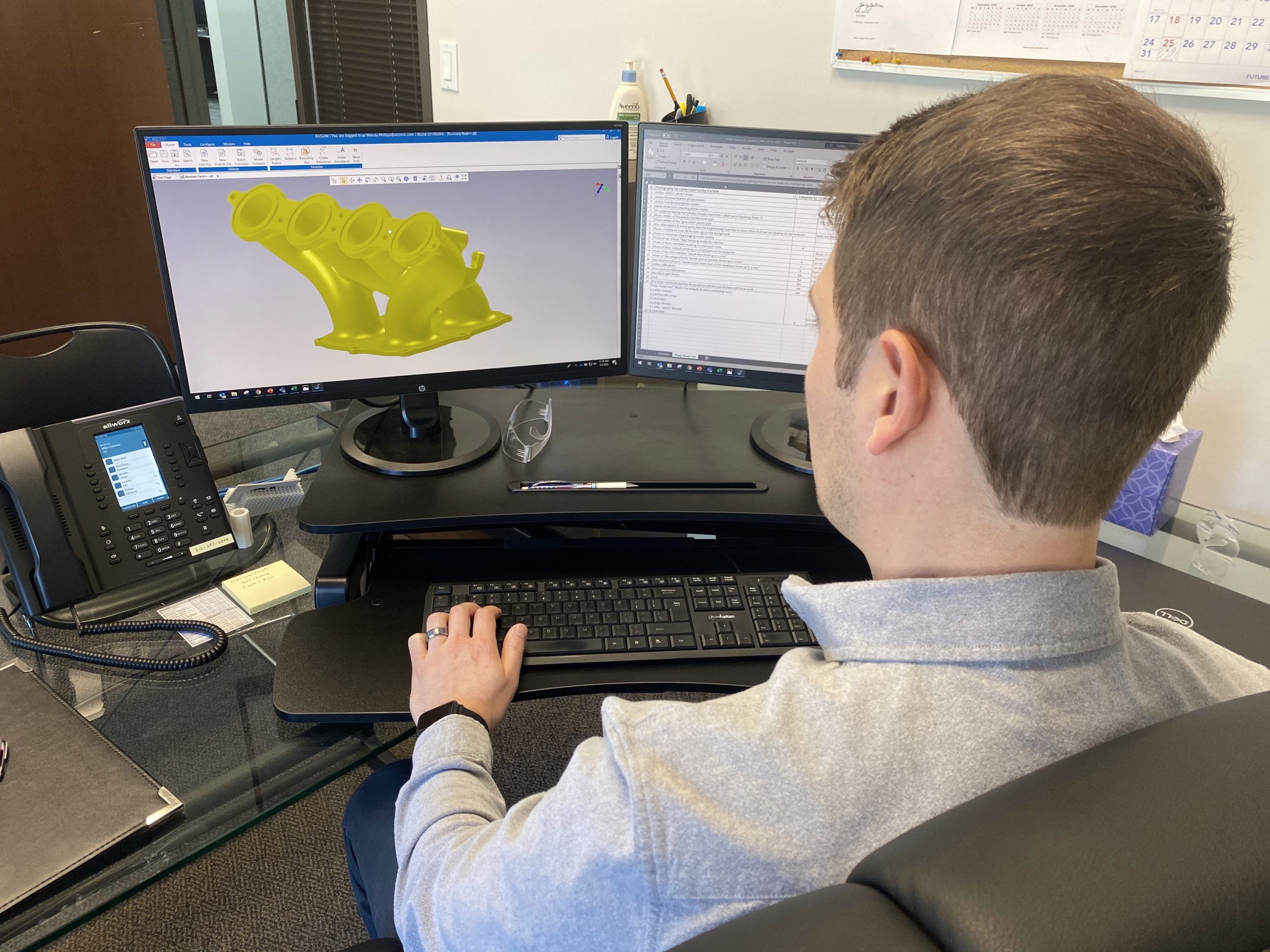

Cumberland Additive is your trusted additive manufacturing leader, providing repeatable quality, fast turn, serial production and high-volume customized precision parts that meet our customer’s critical needs. We provide engineering services and product development assisting with design for additive manufacturing, specific testing and part qualification in metals and polymers. We offer program management and turn-key services through our established fully integrated supply chain.

Cumberland Additive is an experienced additive manufacturing partner who is capable of meeting rigorous aerospace, energy, defense and space requirements.

CAPABILITIES

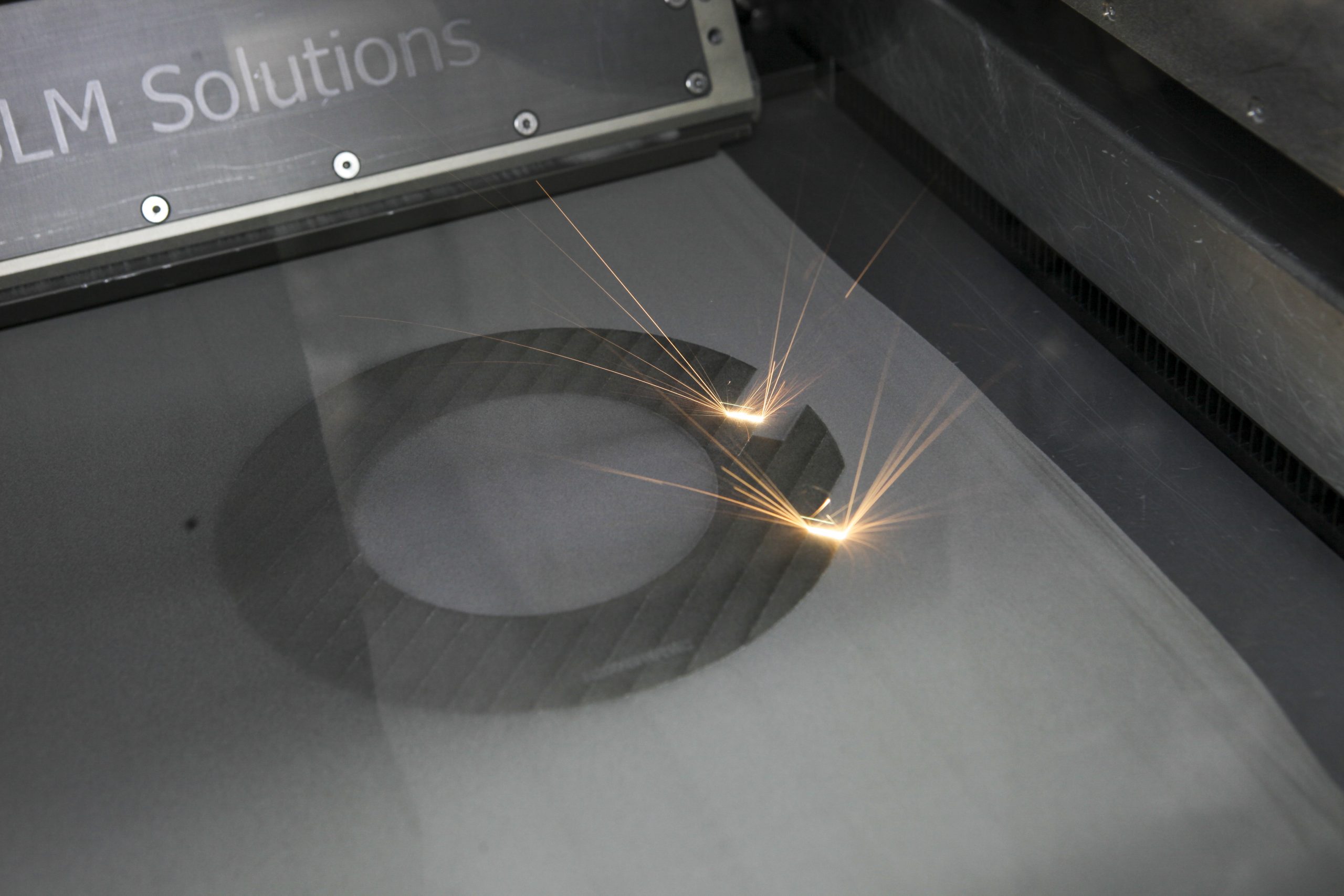

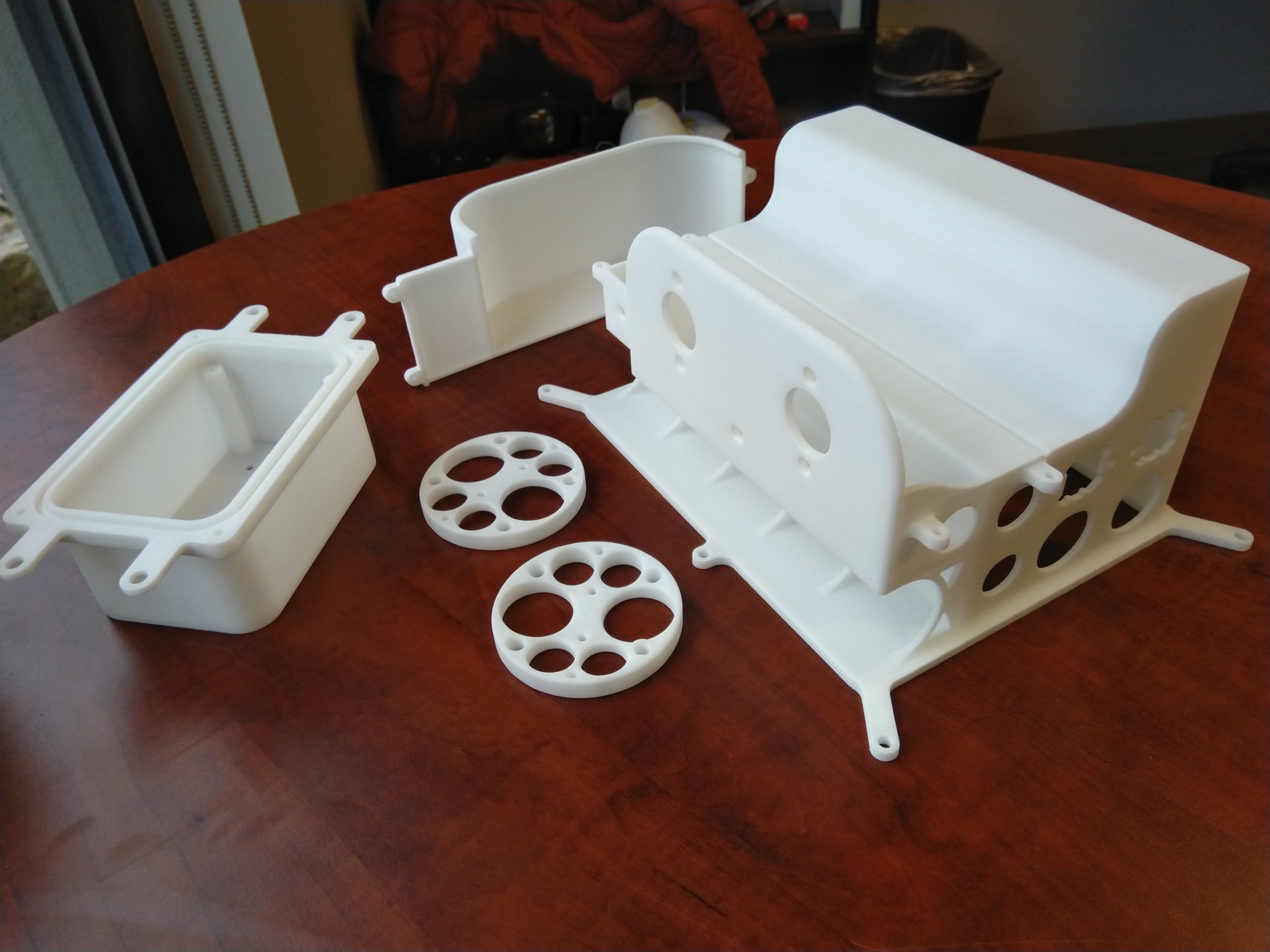

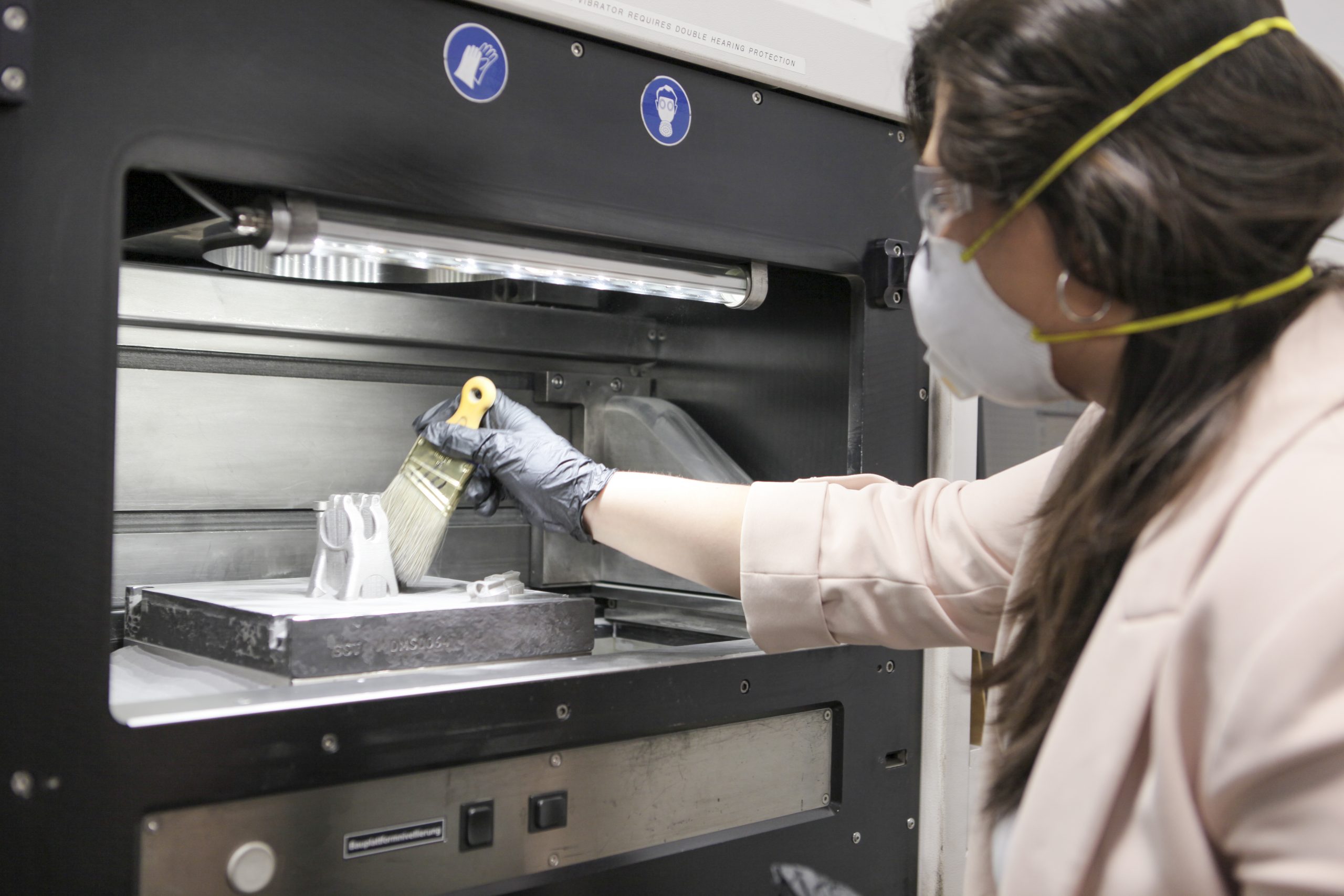

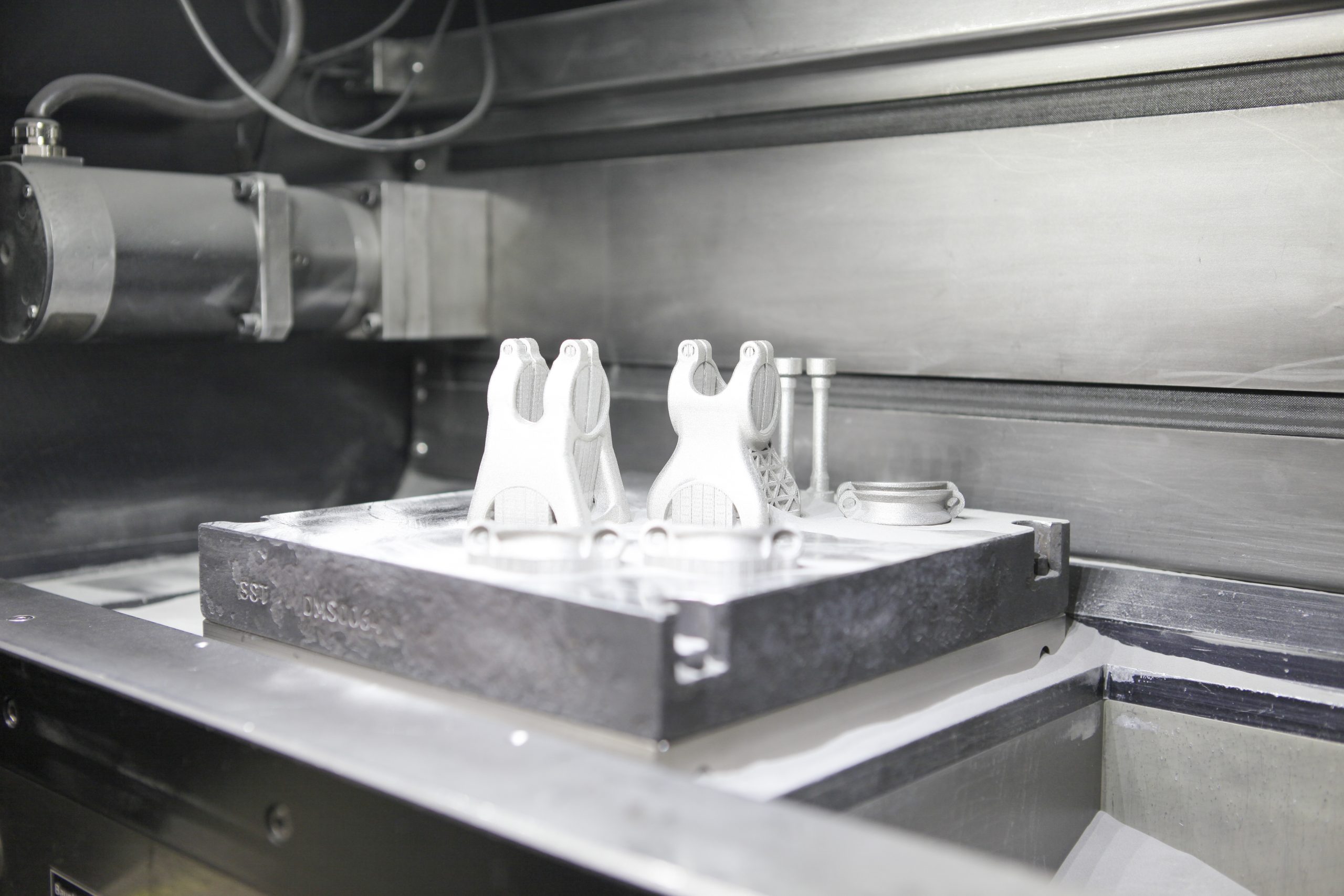

Metal Powder Bed Fusion (PBF)Plastic Selective Laser Sintering (SLS)

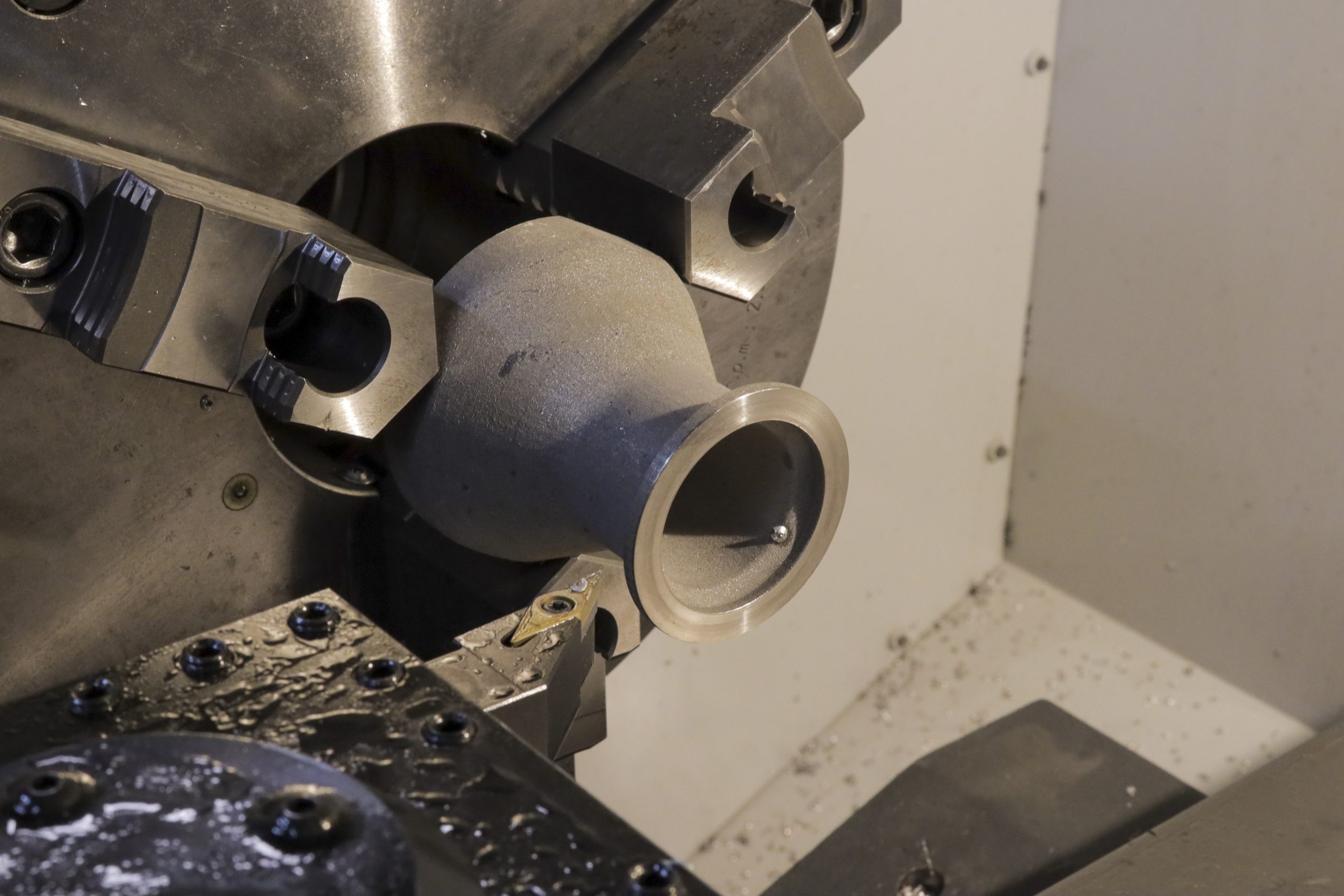

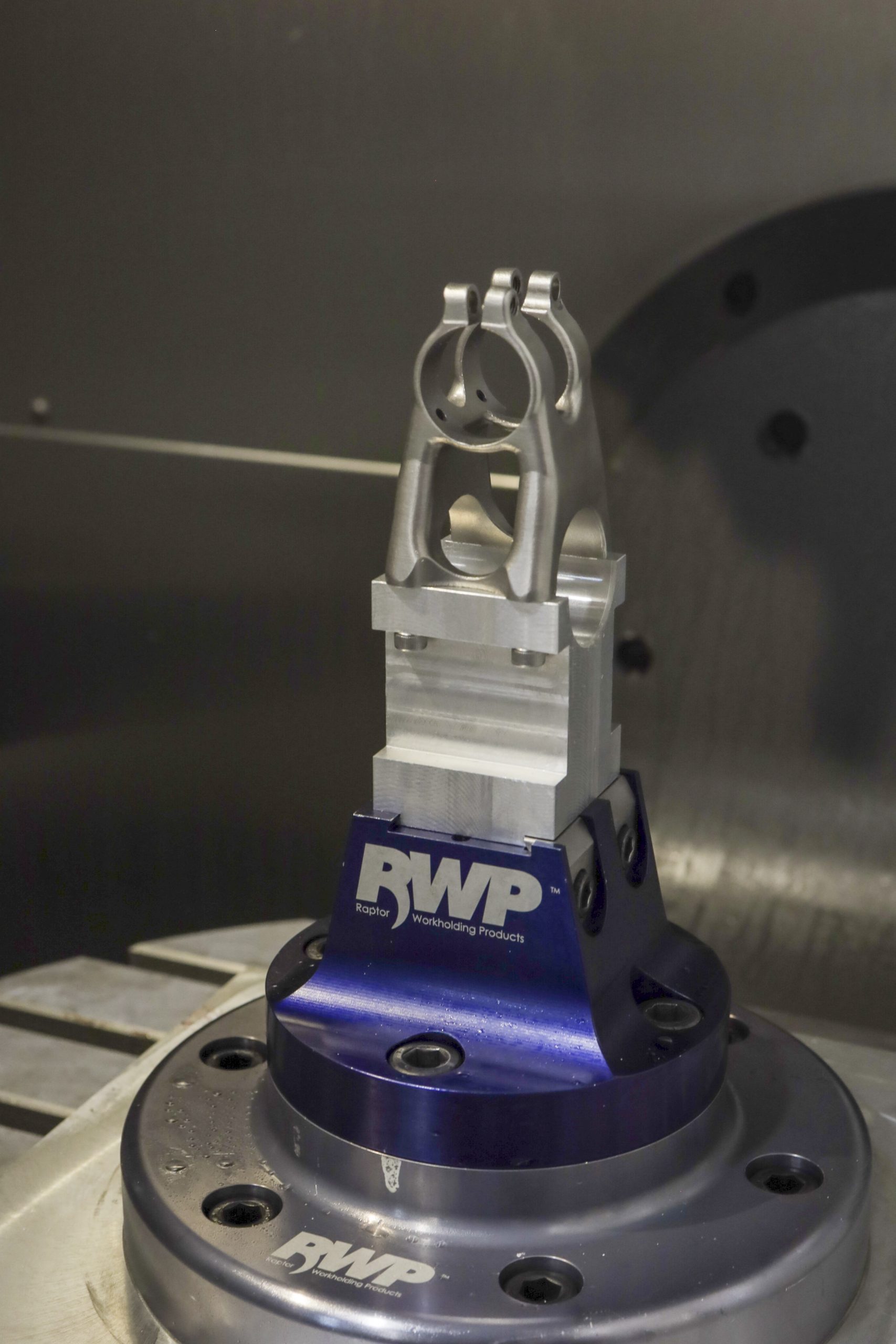

CNC Machining

Metal finishing

Design engineering support

Series Production manufacturing expertise

Quality Inspection, including CMM

Program Management

Turnkey services: Print, Heat treat, Finish, Test, Inspect

MATERIALS

Titanium 6Al-4VNickel: 625, 718, 282

Stainless Steels: 316, 17-4, M300

Aluminum: AlSi10Mg, Scalmalloy, 6061-RAM2

Cobalt-chrome: Stellite 21 AM™, F75

PA 2201 (Nylon 12)

PA 2200 (Nylon 12)

PA D80 (Nylon 11)

FR 106 (Nylon 11)

FR 606 (Nylon 12)

PA 605 (Nylon 12, Alum Filled)

PA 803 CF (Carbon Fiber)

PA 640 (GLS, Carbon Fiber)

PA 616 (GS Nylon 12)

Duraform HST (Composite)

PA 840 (GSL)

Other Materials (enquire)

Machines

3d Printers

SLM 280HL

6 – SLM 280HL

SLM 500HL

1 – SLM 500HL

ARCAM EBM Q20+

2 – Arcam Q20+

JEOL EBM

1 – JAM-5200EBM

EOS M280/M290

12 – EOS M2802 – EOS M290

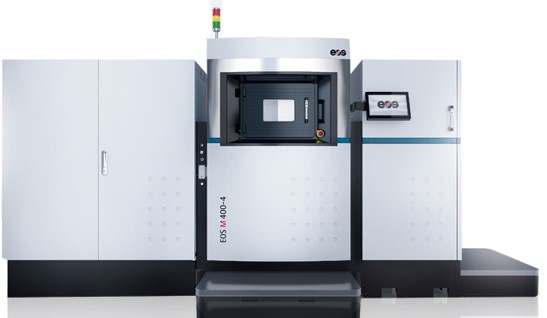

EOS M400

2 – EOS M400-41 – EOS M400-1

EOS Integra

4 – EOS Integra CNC Machines

HAAS 3, 4, 5-AXIS MILLS

9 Machines

HAAS CNC LATHE

2 Machines

SODICK EDM

4 Machines

DMG Mori 5-Axis Mills

2 Machines

Okuma 2, 4, 5-Axis Mills & Lathes

9 Machines Inspection / Test Equipment

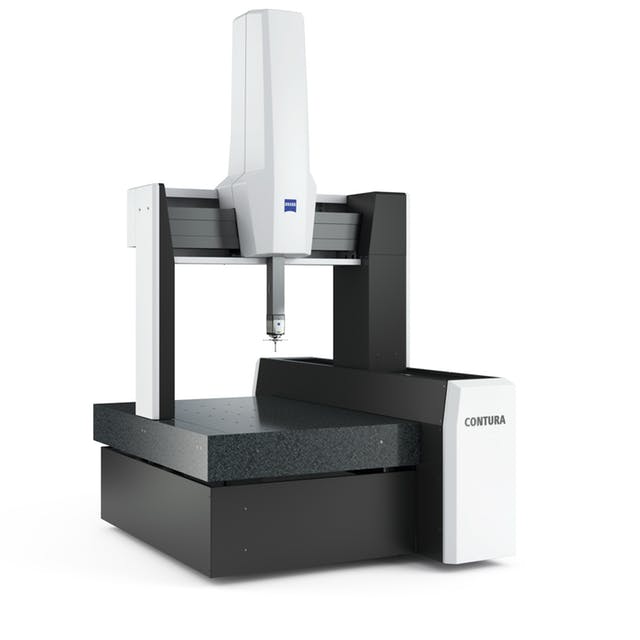

Zeiss Contura CMM

3 – Coordinate Measuring Machines

ATOS BLUE LIGHT

2 – Industrial 3D Scanners

LECO

1 – LECO Chemistry Tester (O&N)

METALLOGRAPHY EQUIPMENT

Services

- L-PBF and E-PBF production printing – Metals and Plastics

- Stress Relief

- Hot Isostatic Pressing (HIP)

- Heat Treatment

- Surface Finishing

- CNC Machining

- Tumble Polishing

- Ultrasonic Cleaning

- Coating and Plating

- Fluorescent Penetrant Inspection (FPI)

- X-Ray

- Computed Tomography (CT)

- Dimensional Inspection using Bench Inspection Equipment, CMM, and Blue Light Scanning

- Mechanical and Chemical Testing

Major Markets

Trusted Partners